Exploring The Ship Part One To The Engine Room (Page Two)

Did you know? - On a ship, the engine room, or ER, commonly refers to the machinery spaces of a vessel. To increase the safety and damage survivability of a vessel, the machinery necessary for operations may be segregated into various spaces, the engine room is one of these spaces, and is generally the largest physical compartment of the machinery space. The engine room houses the vessel's prime mover, usually some variations of a heat engine - diesel engine, gas or steam turbine.

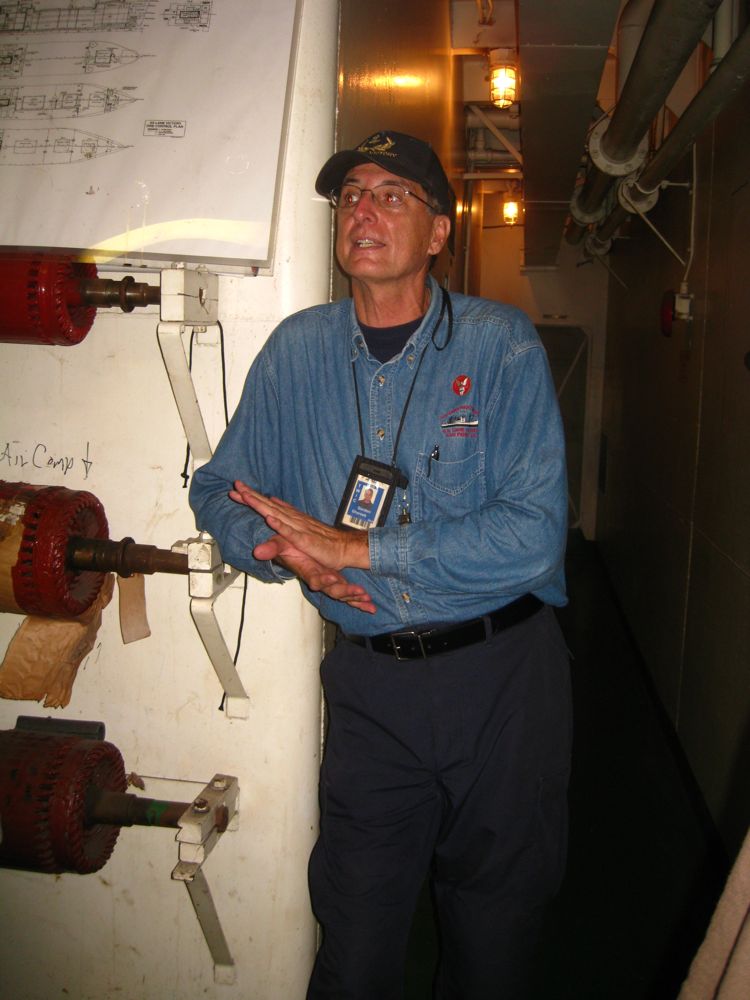

Awaiting our turn

Swapping more stories

The radio call sign!

An excellent explanation of the engine is provided ahead of time!

Ah... Engine room? Sounds scary!

Did you know? - Engine rooms are hot, noisy, sometimes dirty, and potentially dangerous. The presence of flammable fuel, high voltage (HV) electrical equipment and internal combustion engines (ICE) means that a serious fire hazard exists in the engine room, which is monitored continuously by the ship's engineering staff and various monitoring systems.

Brian makes his way to the stairway for our tour

We get to ask questions and are reminded... "Watch out what you touch!"

Jan is brave... A white outfit in the engine room!

Low pressure on the left, high pressure on the right

Did you know? - A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884.

Did you know? - When warming up a steam turbine for use, the main steam stop valves (after the boiler) have a bypass line to allow superheated steam to slowly bypass the valve and proceed to heat up the lines in the system along with the steam turbine. Also, a turning gear is engaged when there is no steam to the turbine to slowly rotate the turbine to ensure even heating to prevent uneven expansion. After first rotating the turbine by the turning gear, allowing time for the rotor to assume a straight plane (no bowing), then the turning gear is disengaged and steam is admitted to the turbine, first to the astern blades then to the ahead blades slowly rotating the turbine at 10 to 15 RPM to slowly warm the turbine.

The high pressure turbine

Did you know? - The control of a turbine with a governor is essential, as turbines need to be run up slowly, to prevent damage while some applications (such as the generation of alternating current electricity) require precise speed control. Uncontrolled acceleration of the turbine rotor can lead to an overspeed trip, which causes the nozzle valves that control the flow of steam to the turbine to close. If this fails then the turbine may continue accelerating until it breaks apart, often spectacularly. Turbines are expensive to make, requiring precision manufacture and special quality materials.

It generates almost 6,000 HP

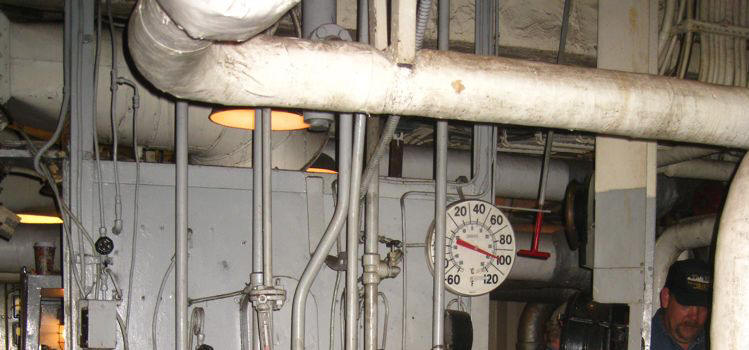

It a cool day... Only 102 degrees!

A plumber's nightmare

The shaft goes to the top of the ship!

Boo! His skin is glowing!

Perspiration is our friends down here

Did you know? - Perspiration (sweating, transpiration, or diaphoresis) is the production of a fluid consisting primarily of water as well as various dissolved solids (chiefly chlorides), that is excreted by the sweat glands in the skin of mammals. Sweat contains the chemicals or odorants 2-methylphenol (o-cresol) and 4-methylphenol (p-cresol), as well as a small amount of urea.

Sue points her ear in order to be able to hear him!

The sky is only six flights up!

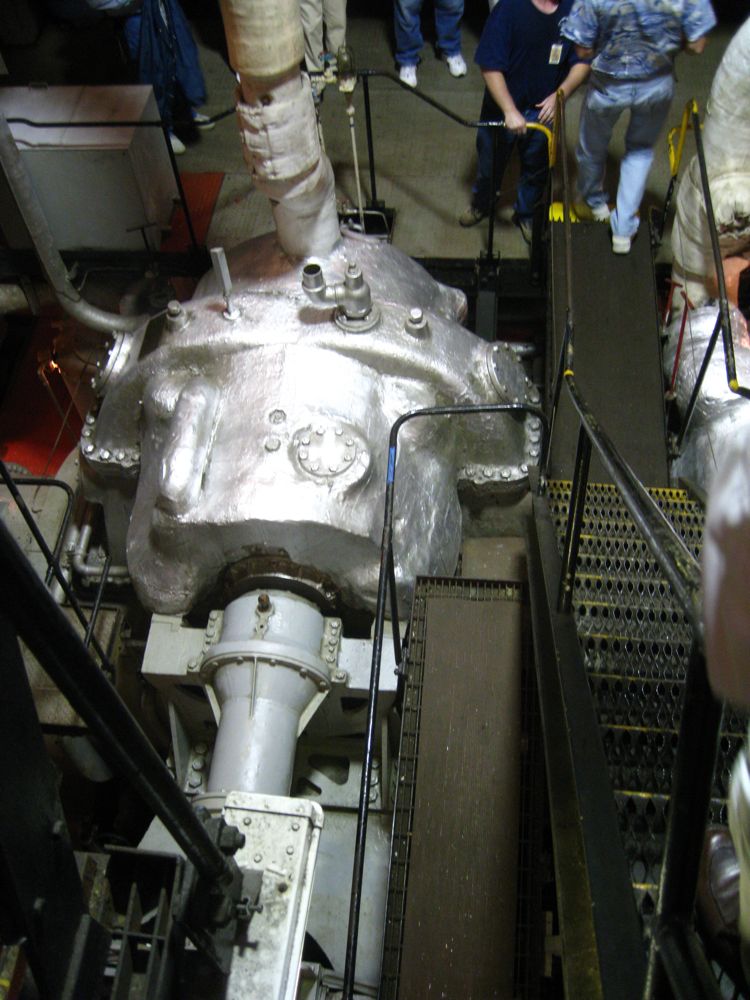

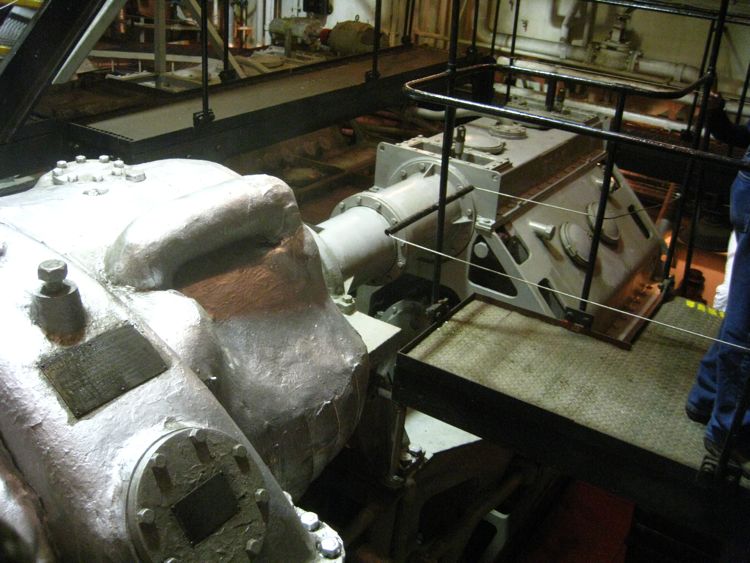

The turbine output goes into the gear reduction

Allis-Chalmers

Did you know? - Allis-Chalmers first entered the manufacturing business as E.P. Allis of Milwaukee in the 1840s.[3] They made waterwheel, sawmill and grindstones. While originally incorporated in Delaware, the company soon became a major manufacturer of steam engines and industrial equipment in the Milwaukee area after merging with other firms—Fraser & Chalmers were a large steel and mining retort manufacturer. The company's presence in Milwaukee became so large that its plants were once used as a landmark there, and, in particular, its "west" plant may have lent its name to the city of West Allis.

Allis-Chalmers entered into the farm equipment business in 1914 at about the time of the World War I. The company would also play a major part as a manufacturer in the World War II building pumps for uranium separation as part of the Manhattan Project and building electric motors for U.S. Navy submarines. Allis-Chalmers also built triple expansion marine steam engines for Liberty ships.

This must be valve heaven!

Did you know? - A valve is a device that regulates the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically pipe fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. ~Wikipedia

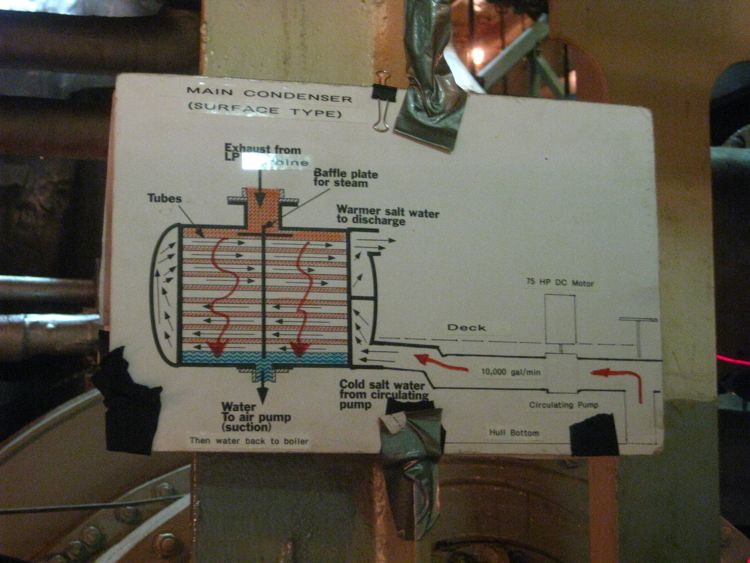

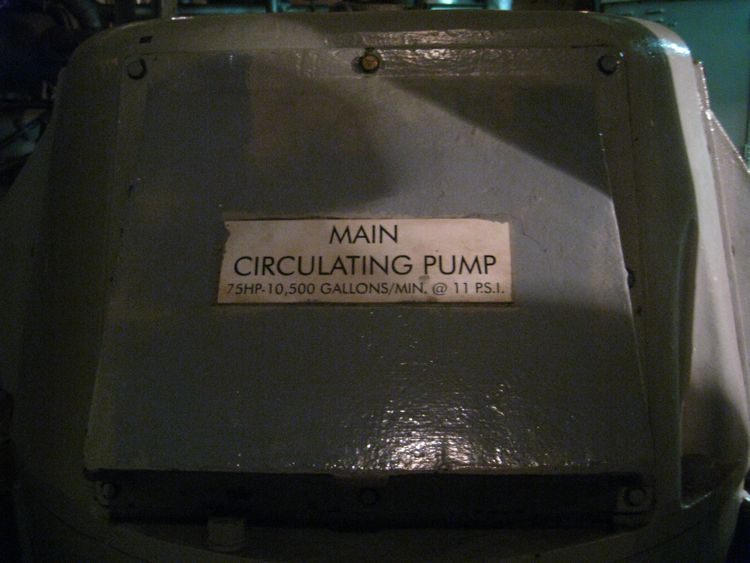

10,000 gallons a minute to cool the steam back into water!

Did you know? - In systems involving heat transfer, a condenser is a device or unit used to condense a substance from its gaseous to its liquid state, typically by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser coolant.

The big valve... Controls seawater flow into the condenser

That means it pumped 4,800,000 gallons of sea water while we were on the adventure!

The condenser

The hydroredigatermalator in action! Huh??

In the belly of the beast... The boiler

Did you know? - A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications. Superheated steam boilers vaporize the water and then further heat the steam in a superheater.

Superheater operation is similar to that of the coils on an air conditioning unit, although for a different purpose. The steam piping is directed through the flue gas path in the boiler furnace. The temperature in this area is typically between 1,300–1,600 degree Celsius (2,372–2,912 °F).

"Do NOT turn any valves you guys!"

Hollywood Brian takes in the lecture

Hold on Jim

Brian enjoying the coolness of "Shaft Alley" - 18" diameter solid steel shaft!

A spare high speed turbine

Gauges and gadgets

Everything seems to be normal here!

"OK, I am cooked... Let's go!"

We Made It Out

Jim shows his Boo Boo from the hot spot he touched in the engine room

They have no idea

We Are Halfway Through The Voyage... Catalina Greets Us