Time To Sail Back Unto History On The Lane Victory 9/24/2011 (Page Three)

Click collage for full sized image

Time For A Memorial Service To The Men And Women Of The Merchant Marine

Did You Know? - The United States Merchant Marine refers to the fleet of U.S. civilian-owned merchant vessels, operated by either the government or the private sector, that engage in commerce or transportation of goods and services in and out of the navigable waters of the United States. The Merchant Marine is responsible for transporting cargo and passengers during peace time. In time of war, the Merchant Marine is an auxiliary to the Navy, and can be called upon to deliver troops and supplies for the military.

Waves And Gulls

Momument In Washington D.C.

Did You Know? - The Navy-Merchant Marine Memorial, located in Lady Bird Johnson Park on Columbia Island in Washington, D.C., is a monument honoring sailors of the United States Navy and the United States Merchant Marine who died at sea during World War I. It was designed in 1922 by Harvey Wiley Corbett and sculpted by Ernesto Begni del Piatta. It was dedicated on October 18, 1934.

Nicknamed "Waves and Gulls," the memorial depicts seven seagulls above the crest of a wave. It is cast from aluminum and the base is made of green granite (the base was originally concrete but replaced by the Works Progress Administration in 1940). It stands 35 feet (10.6 m) tall and 30 feet (9.1 m) wide.

The memorial reads:

"To the strong souls and ready valor of those men of the United States who in the Navy, the Merchant Marine and other paths of Activity upon the waters of the world have given life or still offer it in the performance of heroic deeds this monument is dedicated by a grateful people."

Cornell begins to rope off the memorial area

The honor guard practices ahead of time

Yes... Those are M-1's and they work

Did You Know? - The M1 Garand (officially designated as United States Rifle, Caliber .30, M1 and later simply Rifle, Caliber .30, M1, and also abbreviated as US Rifle, Cal. .30, M1), was the first semi-automatic rifle to be generally issued to the infantry of any nation.[citation needed] Called "the greatest battle implement ever devised" by General George S. Patton,[4] the Garand officially replaced the bolt-action M1903 Springfield as the standard service rifle of the United States Armed Forces in 1936 and was subsequently replaced by the selective fire M14 in 1957.

Picture time...

Almost ready...

Enter the colors...

The story and names belonging to an unfortunate ship was read out load... A sobering experience

As each name was read, a flower was dropped into the ocean

A amazing experience

A rifle salute and prayer ended the ceremony

We Then Raced For The Engine Room

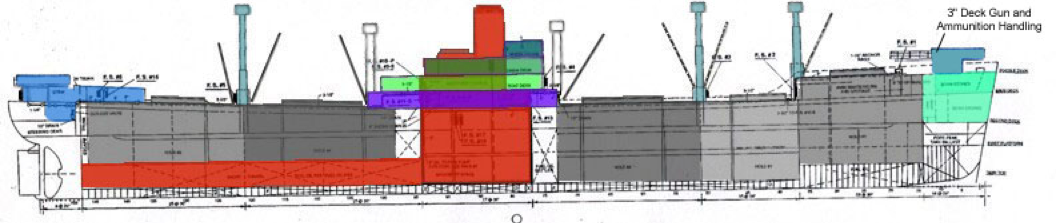

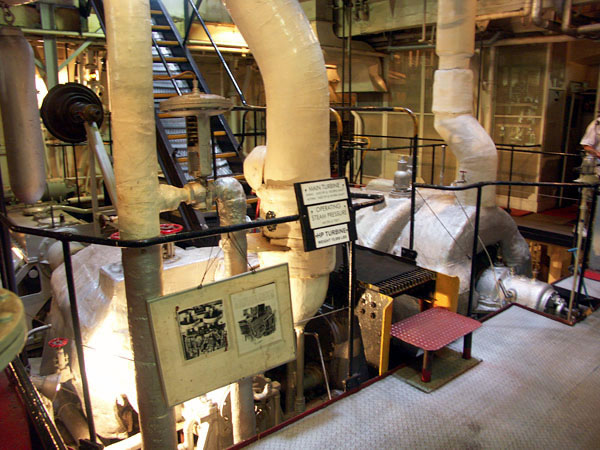

Engine room and shaft alley in red

Gordon does his typically excellent job and readying the tourists for their engine room experience

Hans was our ringer... He worked on engines like this one!

Did You Know? - ringer – Horse racing: An impostor, especially one who misrepresents his or her identity or ability in order to gain an advantage in a competition. Originally used in horse racing, when a fast horse was substituted for a slower one that it resembled (a "ring-in"), the term now applies to any athlete entered in a competition under false pretenses.

We b

First stop: Greg explains how the engine works!

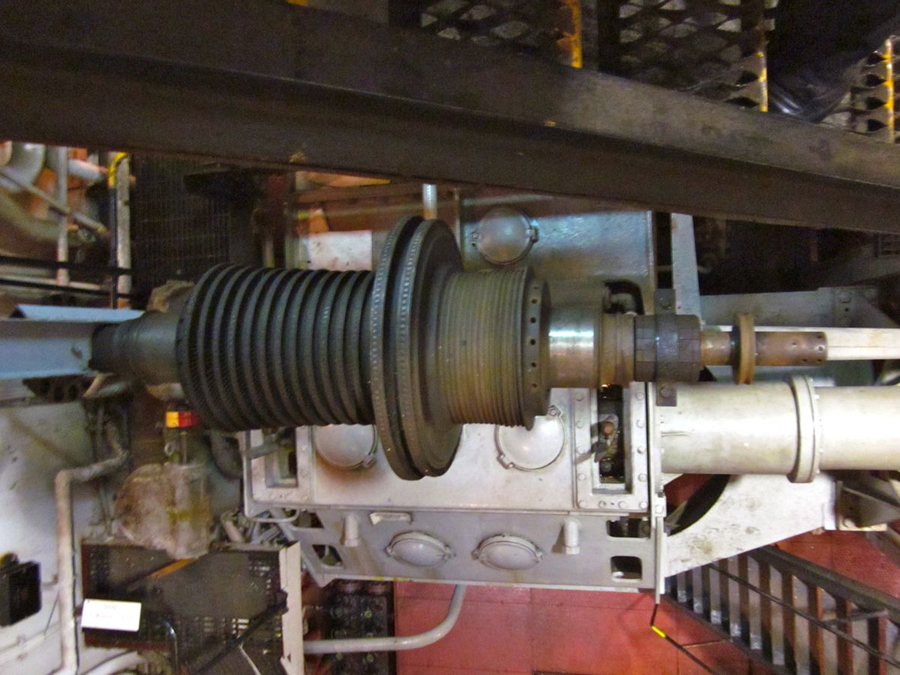

Two turbines drve a double reducton gear box which drives the propeller shaft

Down the ladder we go....

This gentleman is called "The Catcher"... He catches the visitors who miss a step and roll down the ladder

(OK, I made that up!)

Carri is very nimble so she had no problem

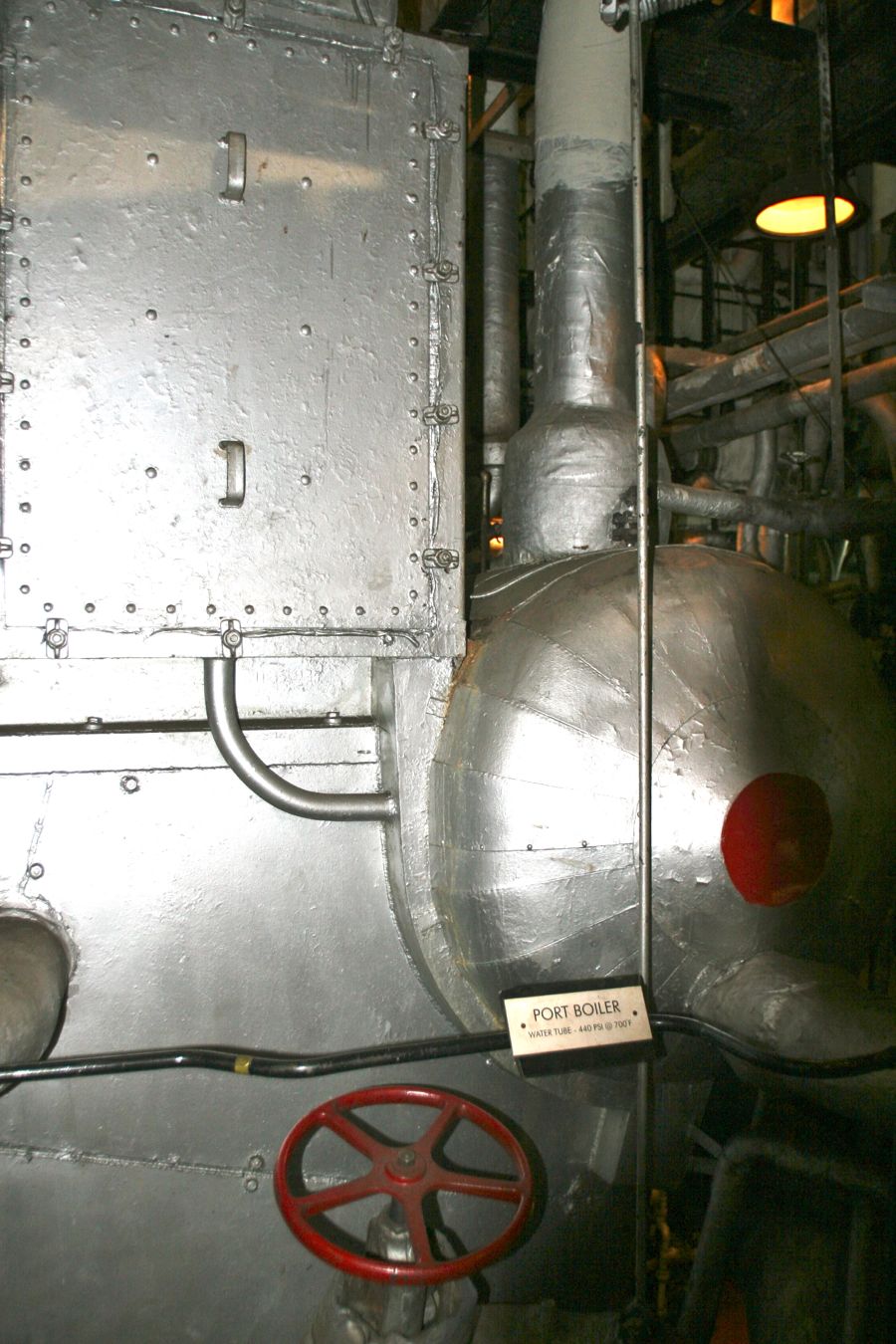

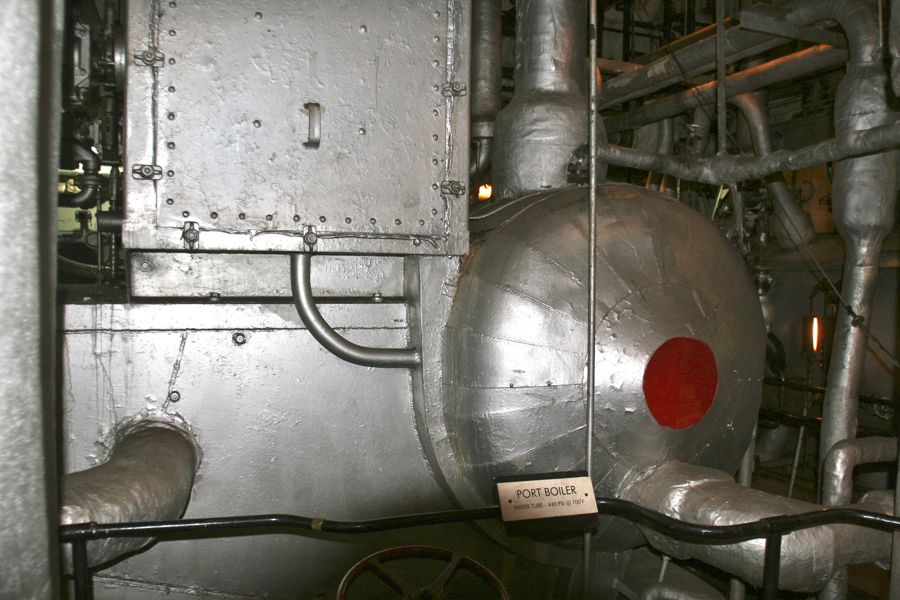

The Heart Of The Engine Is The Boiler and Turbines

The port boiler was doing the job today.. The starboard boiler was out

Did You Know? - Steam is provided by two sectional-header, single-pass design boilers manufactured by Babcock & Wilcox. Rated at 525 psi, with an operating pressure of 465 psi, the boilers produce 27,500 pounds of steam per hour at 750 degrees, with a furnace volume of 450 cubic feet. The boilers are 12 sections wide and are 39-feet, 6-inches athwartship by 11-feet, 8-inches fore and aft, and 21-feet, 3-inches overall height to the top of the economizers. Fitted with interdeck superheaters and economizers, each boiler is fired with water-cooled side walls and refractory in the front and rear walls and floors.

Insulation everywhere....

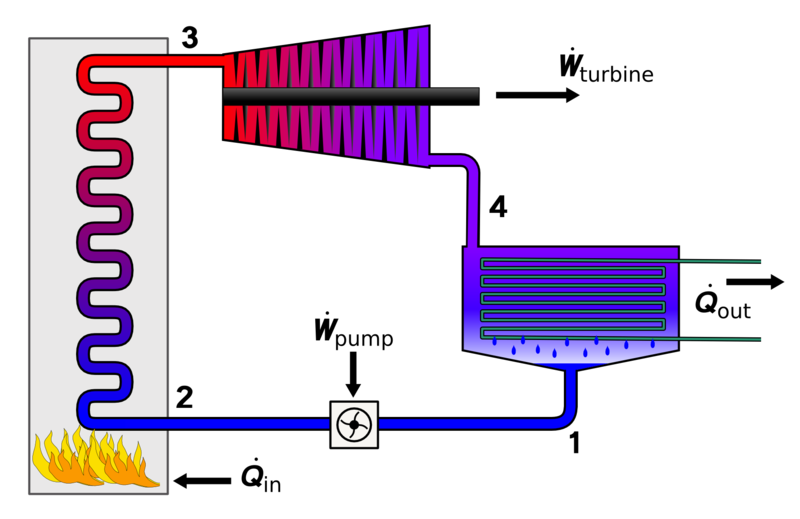

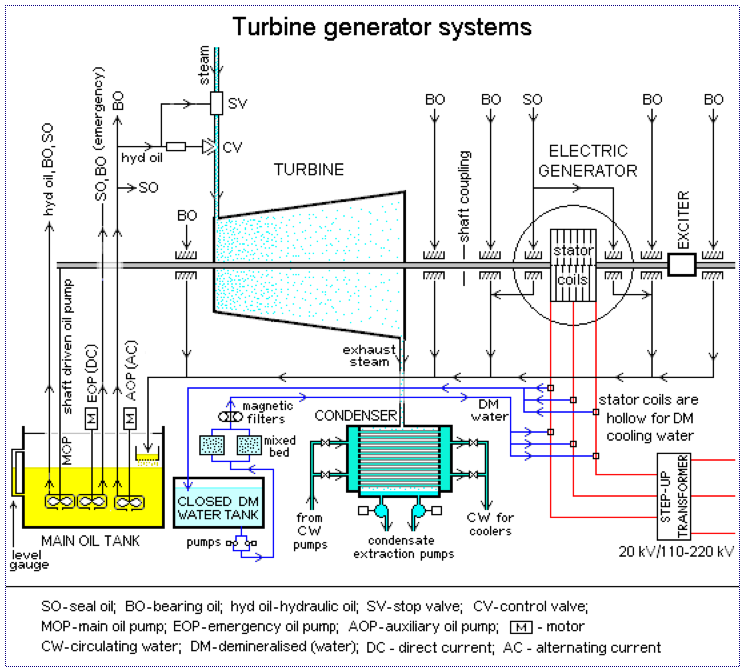

Diagram showing the basic layout of a Rankine cycle; Fluid is pumped to high pressure going from state 1 to 2. Heat is added in the boiler by the burning of fuel (although heat can be added by any method) boiling the fluid to state 3. The vapor expands through the turbine dropping significantly in pressure and temperature to state 4. Finally the vapor is condensed back to a liquid and fed back in the pump.

The superheater is the square box above the boiler - The main advantages of using a superheater are reduced fuel and water consumption but there is a price to pay in increased maintenance costs. In most cases the benefits outweighed the costs and superheaters were widely used.

Wet steam is raised to 750 degrees and becomes a high energy gas before hitting the turbines

"Really Really Hot Water" Spins The Turbines

The low speed turbine at work

The "steam" turns the turbines inside these casings and spins the shaft

- High speed turbine

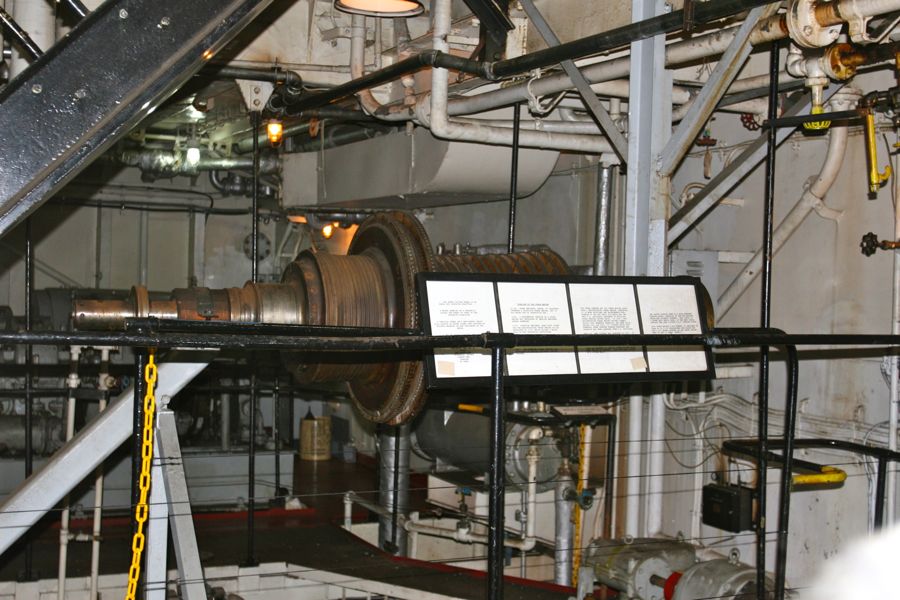

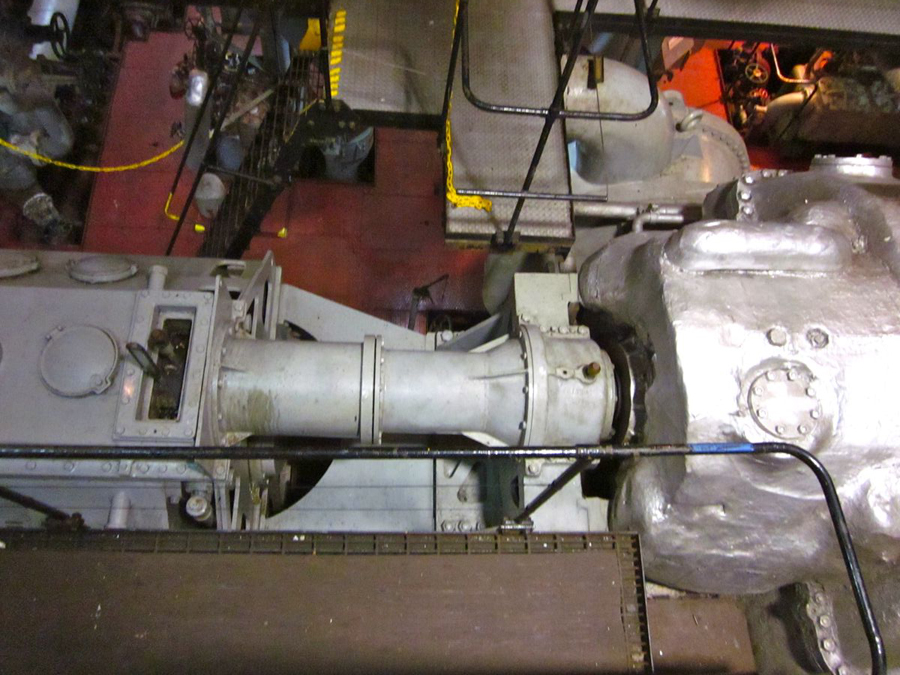

Did You Know? - The main power is derived from two Babcock & Wilcox Boilers. These are oil fired, forced draught, water-tube type boilers with superheaters and economizers. They routinely perform at a pressure of 400 P.S.I. at 750 degrees Fahrenheit. They each have 6000 sq. ft. of heating surface, plus an additional 2400 sq. ft. provided by the superheaters and economizers. The power derived from the boilers is used to run the high and low pressure turbines. The turbines are coupled through cross-compound, double reduction gears which drive a 16" by 166' shaft.

High and low speed turbines sent their power into a gearbox

An actual turbo ne waiting in a spare position in case it is needed

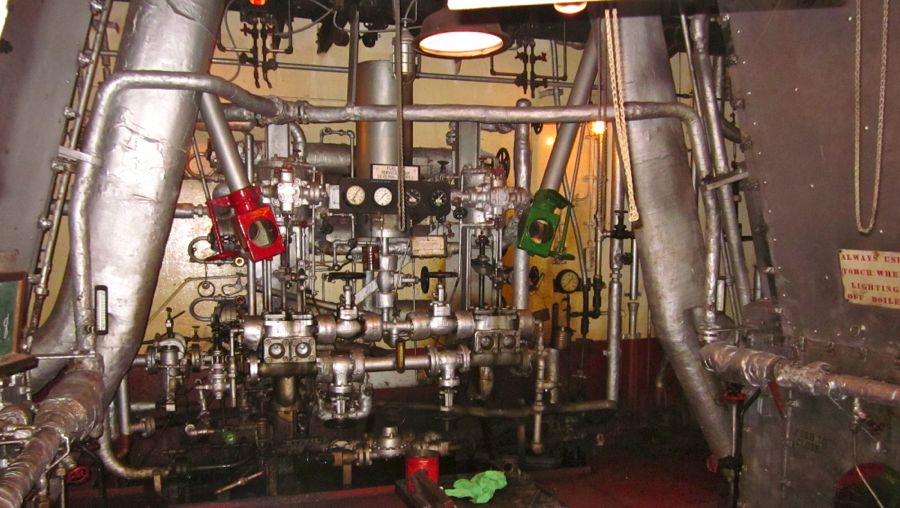

Simple but loads of valves and plumbing are required to make it run

Gear box on the left... Turbine on the right

Plan view of the high speed turbine

The oil used in the turbine is viewable through a window... If the oil stops, there is five minutes left before the turbine freezes up!

Everyone keeps and eye on the oil

Loads of oil to keep this puppy lubricated

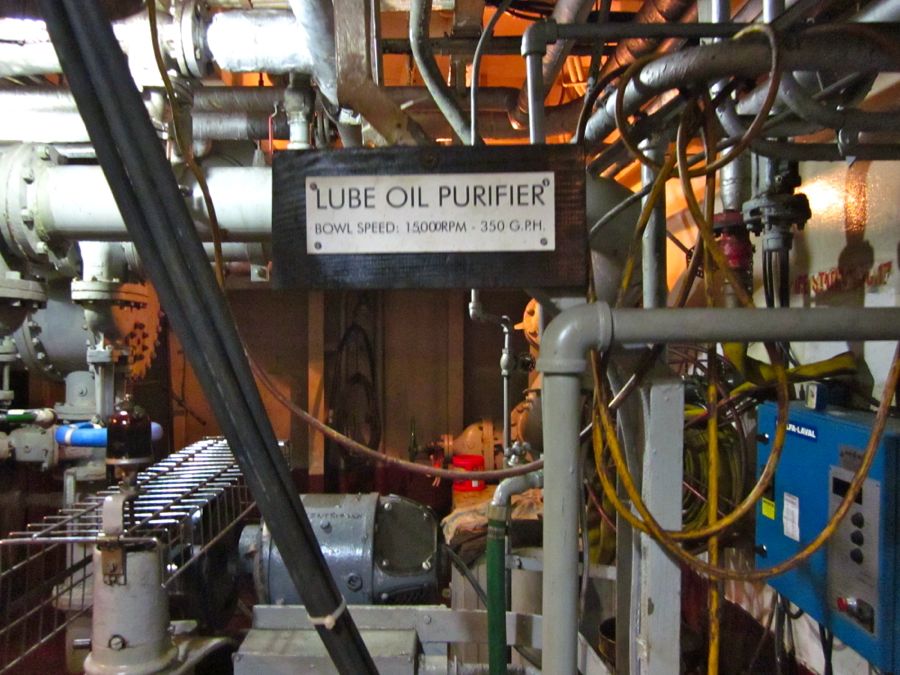

One must clean the oil while underway....

Did You Know? - A centrifugal oil cleaner is a rotary sedimentation device using centrifugal force rather than gravity to separate contaminants from the oil, in the same manner as any other centrifuge. Pressurized oil enters the center of the housing and passes into a drum rotor free to spin on a bearing and seal. The rotor has two jet nozzles arranged to direct a stream of oil at the inner housing to rotate the drum. The oil then slides to the bottom of the housing wall, leaving particulate oil contaminants stuck to the housing walls. The housing must periodically be cleaned, or the particles will accumulate to such a thickness as to stop the drum rotating. In this condition, unfiltered oil will be recirculated.

15,000 RPM will certainly clean the oil....

Valves everywhere

Oil id essential in keeping the engineer room moving

The boiler plumbing to the left of the boiler

In the heart of the beast.... Hotter than "H E double-toothpicks"

Mike explains about the boiler operation

How Much Sea Water Is Used Every Minute?

The main sea water pump.... 75 HP moving 10,500 gallons of sea water a minute in

order to cool the steam so it can go into the boiler again

Hans explains the details to Kirsten

The main inlet valve that controls sea water flow into the cooling system

An amazing array of valves

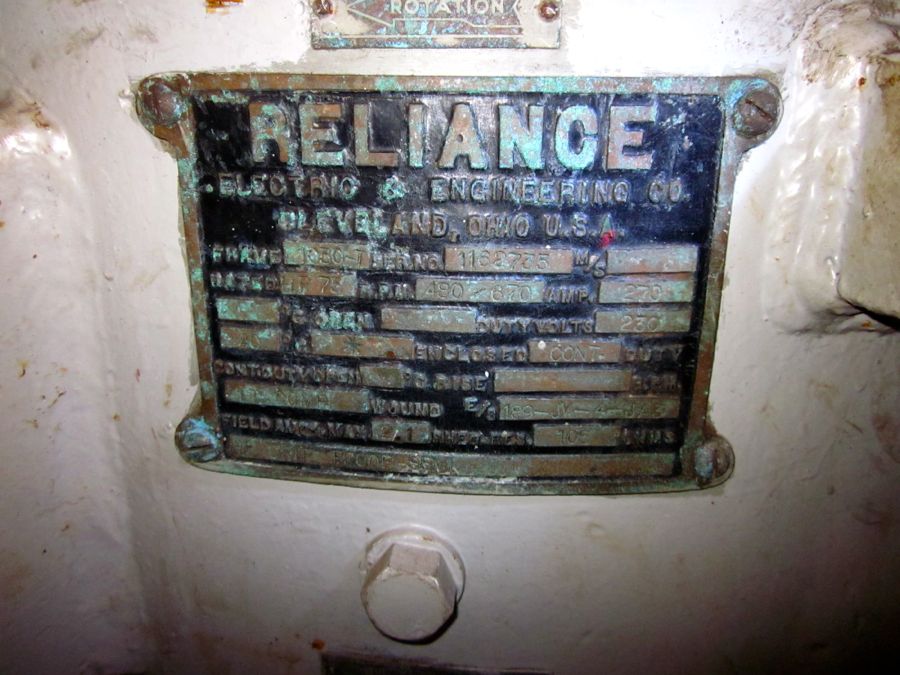

Still has the original tags

- During World War II, Reliance served as a primary supplier of motors to the military, especially the Navy. The company also supplied the motors needed to build hundreds of tanks.

In 1998 Reliance Electric Motors joined DODGE Mechanical to form Rockwell Automation’s Power Systems Business in Greenville, SC.

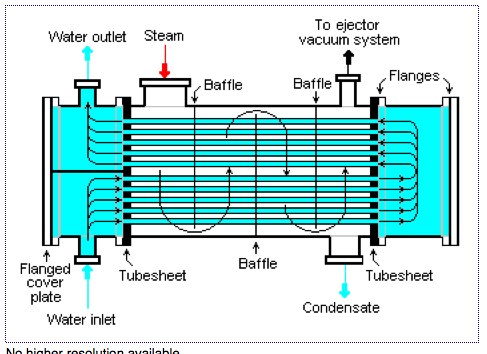

The Condensers Were Working Overtime

Steam in one end and water out the other with 10,500 gallons per minute of sea water to help

Did You Know? - Surface condenser is the commonly used term for a water-cooled shell and tube heat exchanger installed on the exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however significantly more expensive and cannot achieve as low a steam turbine exhaust pressure as a water cooled surface condenser.

Did You Know? - The steam turbine itself is a device to convert the heat in steam to mechanical power. The difference between the heat of steam per unit mass at the inlet to the turbine and the heat of steam per unit mass at the outlet to the turbine represents the heat which is converted to mechanical power. Therefore, the more the conversion of heat per pound or kilogram of steam to mechanical power in the turbine, the better is its efficiency. By condensing the exhaust steam of a turbine at a pressure below atmospheric pressure, the steam pressure drop between the inlet and exhaust of the turbine is increased, which increases the amount of heat available for conversion to mechanical power. Most of the heat liberated due to condensation of the exhaust steam is carried away by the cooling medium (water or air) used by the surface condenser.

The main pump and condenser are just a few feet apart

Plumbing everywhere

Between the boilers

Secondary condensers are in the secondary steam system and used for generating the ships electrical system

Did You Know? - Electrical power is provided by an inboard and outboard turbo-generators, the turbines manufactured by the Joshua Hendy Iron Works of San Francisco, California, and the generators manufactured by the Allis-Chalmers Company, Milwaukee, Wisconsin. The three-wire marine direct current generators produce 300-kilowatts, with 120 and 2140 volts and 1250 amps and 1200-rpm. The ship also has emergency diesel generators in the engine room and in the emergency diesel room. The steering gear, a slide electro-hydraulic, double-ram type, was manufactured by the Baldwin Locomotive Company, and is located aft.

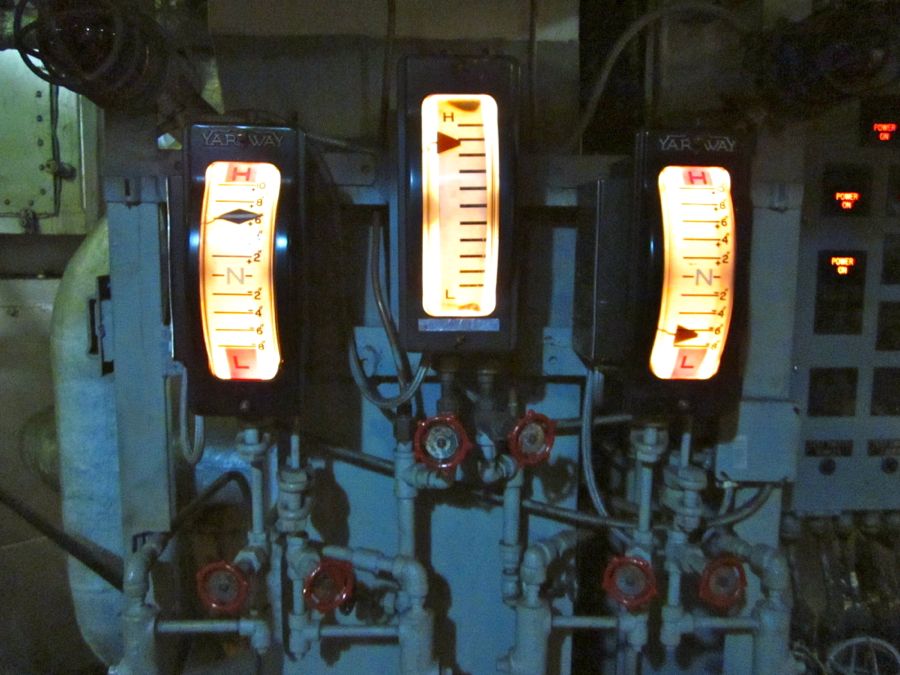

Dial nightmares

"I think I will turn a wheel and see what happens

Great meters... Easy to see

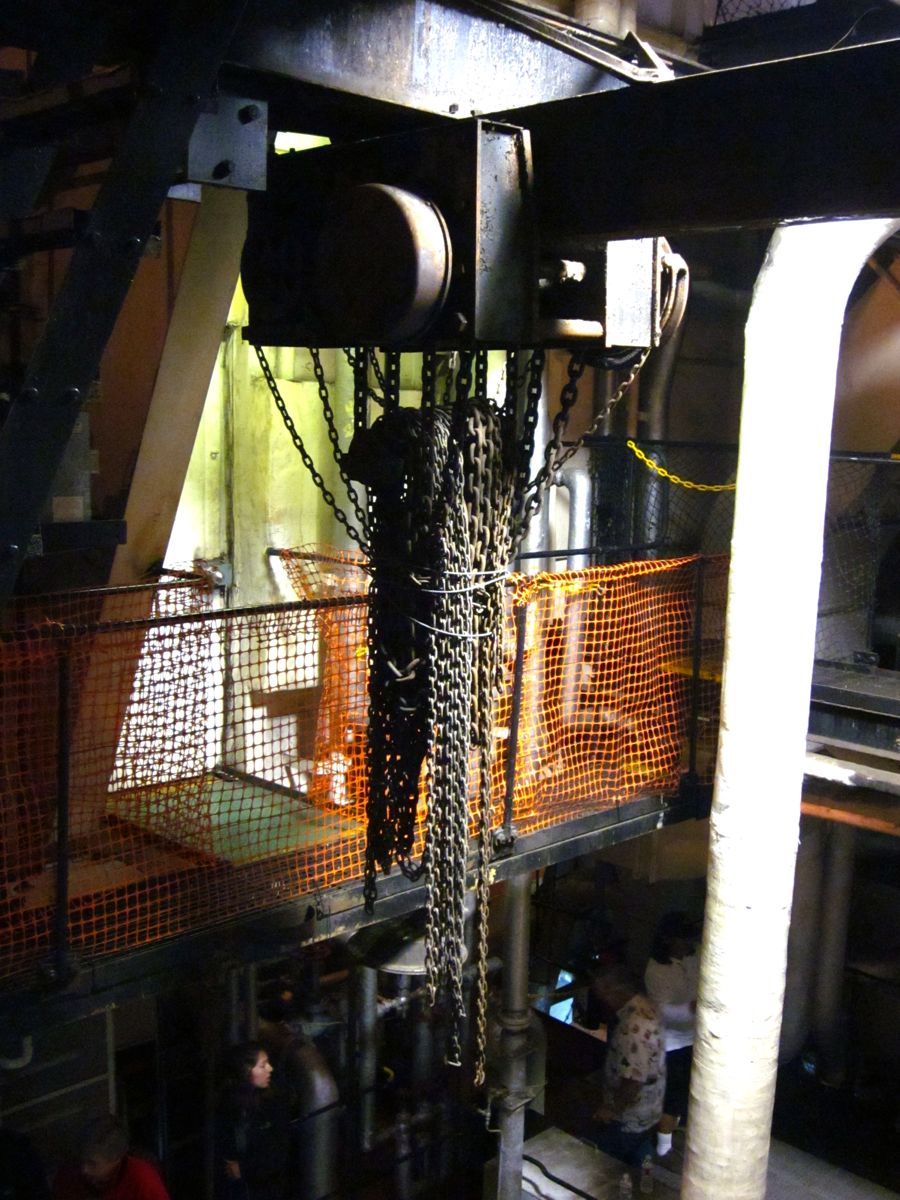

Overhead cranes built into the ship

Looking up to the sky from deep inside